PRT designs and builds

custom stirrers & reactors

for slurry and gasphase use,

according to your needs.

At PRT GmbH we combine process knowledge with state of the art CAD-modeling to miniaturize your process.

Together with our partners we are able to design and deliver ASME or (DGRL) 2014/68/EU certified reactors.

All of our designs are extensively tested before delivery.

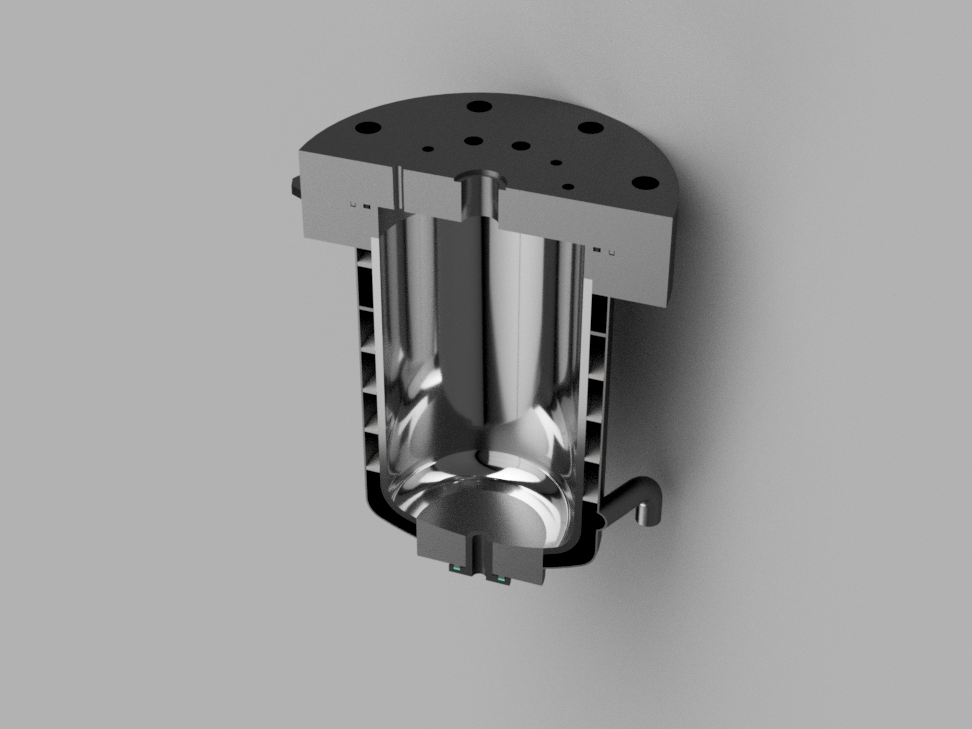

Example: 12l reactor with ASME certificate

- Maximum pressure: 70 barg

- Maximum temperature: 120 °C

- Good heat transfer to jacket medium

Coldflow experiments:

- vessels up to 350 x 350 x 350 mm can be produced within a day

- different stirrer designs can be produced withing hours

- design freedom due to the use of 3d- printing